Welcome to the realm of technological marvels, a domain where innovative minds converge and ideas materialize into extraordinary inventions. Within this realm, where magic lies in the hands of creators, a symphony of craftsmanship brings forth the wonders of the modern era. In this section, we explore the intricate process behind the birth of unparalleled tablets, devices that have revolutionized the way we connect, learn, and discover.

Embark upon a journey that takes you deep into the heart of tablet production, where every step is guided by meticulous precision. Witness the fusion of artistry and technology that goes into the creation of these sleek and powerful gadgets, unrivaled by any other. Throughout this captivating exploration, you will delve into the secret chambers where visionaries unite to breathe life into their imagination, channeling their passion and expertise into the very essence of these captivating companions.

Delve into the realms of engineering and design as you discover the myriad components that harmoniously intertwine to form the essence of a tablet. Explore the anatomy of these devices, uncovering the synergistic collaboration between hardware and software. From the elegant engineering of the outer shell to the intricate circuitry within, every aspect of tablet creation is a labor of dedication and innovation. The marriage between form and function becomes evident as you traverse the intricate labyrinth of assembly lines and technical prowess.

Steps to Manufacture iPads: From Design to Production

This section will explore the intricacies involved in the production process of iPads, from the initial design phase to the final manufacturing stages. It encompasses a series of crucial steps that lead to the creation of this innovative and popular device.

In order to bring the concept of iPads to life, the design phase serves as an essential starting point. Teams of skilled designers and engineers collaborate to create detailed blueprints and models that encapsulate the vision and functionality of the device. These designs undergo careful scrutiny and refinement to ensure a seamless user experience and optimal performance.

Once the design phase is complete, the manufacturing process kicks into gear. The first step involves sourcing high-quality materials, such as durable metals and lightweight polymers, which form the foundation of the iPad's structure. These materials are carefully selected to meet stringent standards of quality and durability.

Next, the components that make up the internal hardware of the iPad are meticulously manufactured. This includes the production of the processor, graphics card, memory chips, and other integral parts. Each component undergoes rigorous testing and quality control to ensure optimal performance and reliability.

Simultaneously, the assembly of the iPad takes place. Skilled technicians carefully piece together all the manufactured components, ensuring precise placement and proper connectivity. This stage requires a delicate balance of manual dexterity and advanced technology to create the sleek and functional design of the iPad.

Following the assembly, extensive testing is conducted to ensure the iPad functions flawlessly. This includes testing the display quality, touch sensitivity, wireless connectivity, and overall performance. Defective devices are identified and set aside for further troubleshooting, while those that pass the rigorous testing regimen move on to the final phase.

Once the iPads have passed all quality control checks, they are prepared for shipping and distribution. This involves packaging them in protective material and labeling them according to their respective models and configurations. The iPads are then dispatched to retailers and customers worldwide, ready to be embraced by technology enthusiasts.

| Design Phase | Manufacturing Materials | Component Production |

|---|---|---|

| • Skilled designers & engineers collaborate on blueprints and models. | • High-quality materials sourced for durability and functionality. | • Manufacturing of processors, graphics cards, memory chips, etc. |

| Assembly | Testing | Shipping and Distribution |

| • Precise placement and connectivity of manufactured components. | • Extensive testing to ensure flawless functionality. | • Packaging and labeling for distribution worldwide. |

Understanding the Concept and Designing the iPad

When delving into the intricacies of the iPad, it is imperative to grasp the fundamental concept behind its creation and the meticulous design process that goes into its development. In order to fully understand the iPad, one must explore the underlying principles and considerations that shaped its inception.

Understanding the concept of the iPad entails breaking down its purpose and functionality. The iPad is not merely a device, but rather a multifaceted tool that seamlessly integrates technology, portability, and versatility. It provides users with a platform for various activities, ranging from leisurely entertainment to professional productivity.

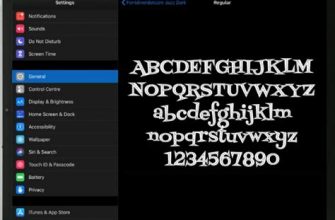

Designing the iPad involves a harmonious blend of aesthetics and functionality. Apple, the trailblazing company behind its conception, meticulously crafts each aspect of the device to offer a sleek and intuitive user experience. The design process encompasses careful consideration of factors such as form factor, display technology, processor performance, and battery life.

One vital aspect of iPad design is the incorporation of materials that ensure durability without compromising elegance. Apple employs premium materials like aluminum and glass, not only for their aesthetic appeal but also for their ability to withstand daily use and maintain structural integrity.

Moreover, the ergonomics of the iPad are a crucial consideration. From the weight distribution to the placement of buttons and sensors, every aspect is thoughtfully designed to enhance comfort and minimize user fatigue during extended usage periods.

| Key Features | Benefits |

| Retina Display | Crystal-clear visuals and enhanced viewing experience |

| A10 Fusion chip | Efficient performance for seamless multitasking and gaming |

| Smart Keyboard compatibility | Enhances productivity with a full-sized keyboard |

| Touch ID technology | Secure and convenient authentication method |

By understanding the concept and design principles of the iPad, one gains a deeper appreciation for the amalgamation of innovation and craftsmanship that has brought this revolutionary device to life. The iPad continues to evolve and redefine the parameters of portable computing, solidifying its position as a pinnacle of technological achievement.

Sourcing and Acquiring the Necessary Components for iPad Production

In order to bring forth the exceptional technological marvel known as iPads, a comprehensive and intricate process must take place. This section aims to shed light on the vital steps involved in sourcing and acquiring the essential components to construct these innovative devices. Without the proper procurement of each component, the production of iPads would be hindered and their exceptional features would not come to fruition.

One fundamental aspect involved in the production of iPads is the careful selection and acquisition of various components. These components encompass a wide range of materials, including but not limited to advanced processors, high-quality display panels, intricate circuit boards, durable casings, and reliable batteries. Each component contributes its unique characteristics to the overall functionality, performance, and aesthetic appeal of an iPad.

Ensuring a consistent and reliable supply chain is crucial to the iPad manufacturing process. Coordinating with trusted suppliers and industry partners enables the seamless acquisition of components. In order to meet the colossal demand for iPads worldwide, manufacturers must establish strong relationships with suppliers capable of consistently delivering the required components in a timely manner.

A critical aspect of sourcing components for iPads involves thorough quality control measures. Establishing stringent standards and conducting rigorous evaluations helps guarantee that every component acquired meets the exact specifications and performance requirements set forth by the iPad manufacturer. This meticulous attention to quality not only ensures the production of reliable and high-performing iPads but also ensures customer satisfaction and loyalty.

To aid in the management and tracking of the vast array of components, manufacturers employ sophisticated inventory management systems. These systems enable real-time monitoring of component inventory levels, facilitate efficient reordering processes, and help prevent any potential disruptions in the production line. The effective management of component inventory plays a pivotal role in ensuring a smooth and uninterrupted manufacturing process.

In conclusion, the sourcing and acquisition of necessary components for iPad production involves a complex and well-coordinated effort. From selecting high-quality components to establishing robust supplier relationships and implementing rigorous quality control measures, each step is essential to create iPads with exceptional functionality and performance. The ongoing advancements in technology drive the need for continuous improvement in sourcing strategies to meet the demands of the ever-evolving market.

Assembly and Testing: Building the iPad

Once all the necessary components have been manufactured and prepared, the process of constructing an iPad begins. This stage involves the assembly of various intricate parts that come together to form the iconic device we know today.

Firstly, the internal circuitry and components are carefully connected and secured inside the iPad casing. This includes the motherboard, processor, memory chips, and other crucial electronic elements that make the device operate smoothly. These delicate parts need to be handled with precision and expertise to ensure they are connected correctly and securely.

Next, the display panel is attached to the motherboard, allowing the device to showcase images and videos in stunning clarity. This high-resolution screen is a critical feature of the iPad, and its installation must be flawless to provide a top-quality visual experience. Attention to detail and meticulous alignment is required to make sure the display is perfectly positioned within the casing.

After the internal components and display have been assembled, the iPad undergoes a series of rigorous tests to ensure its functionality and performance. The device is powered on and subjected to thorough quality control procedures, including checking the touchscreen responsiveness, camera capabilities, audio output, and connectivity features. Any defects or malfunctions are identified and promptly addressed to guarantee the final product meets the high standards set by Apple.

Assembly and testing are integral processes in the creation of an iPad. The meticulous craftsmanship and attention to detail during assembly, coupled with the comprehensive testing procedures, result in a reliable and efficient device. From the intricate internal connections to the flawless display integration, every step of the assembly process is crucial in bringing the iPad to life.

Ensuring Quality: Control and Inspection Processes

In the production of technologically advanced devices like iPads, maintaining high quality standards is crucial. To achieve this, a series of well-defined control and inspection processes are implemented throughout the manufacturing process. These processes are designed to detect and rectify any potential defects or inconsistencies in the iPads being manufactured, ensuring their reliability and functionality in the hands of consumers.

Quality control begins right from the initial stages of manufacturing, where raw materials are thoroughly inspected before being used in the production process. This includes scrutinizing the components and sub-assemblies that form the foundation of the iPads, such as the screens, processors, batteries, and connectors. By ensuring the quality of these components, the risk of defects or malfunctions in the final product is minimized.

Once the assembly of iPads is underway, rigorous inspection procedures are employed at various stages to identify and correct any potential issues. This typically involves visual inspection, functional testing, and performance checks to ensure that each iPad meets the required standards. Through a combination of automated testing and manual inspection, potential problems like screen defects, battery performance, or connectivity issues can be identified and resolved promptly.

In addition to ensuring the technical aspects of the iPads, quality control also encompasses the aesthetic elements. Visual checks are conducted to guarantee that the devices exhibit a flawless exterior finish, with no visible scratches or imperfections. Attention to detail during the inspection process ensures that customers receive a visually appealing product that aligns with their high expectations.

The implementation of effective quality control and inspection processes serves as a testament to the commitment of iPad manufacturers towards delivering reliable and superior products. By continuously monitoring and evaluating the iPads throughout the production process, any potential deviations from the desired quality benchmarks are promptly identified and addressed, resulting in a consistently high standard of iPads that consumers can rely on.

| Benefits of Quality Control and Inspection Processes: |

|---|

| 1. Enhanced customer satisfaction through the delivery of reliable and defect-free iPads. |

| 2. Reduction in product recalls or returns, leading to cost savings for the manufacturer. |

| 3. Improved brand reputation and customer loyalty, fueling future sales and growth. |

| 4. Higher chances of uncovering potential design or manufacturing flaws, allowing for timely improvements. |

| 5. Compliance with industry standards and regulations, ensuring the iPads are safe for use. |

Packaging and Distribution of Apple Tablets

In this section, we will delve into the crucial aspects of packaging and distribution when it comes to delivering innovative Apple tablets to consumers worldwide. From protective casing to efficient logistics, every step of the journey will be explored to ensure a seamless delivery of these cutting-edge devices.

Product Packaging Apple spares no expense when it comes to the presentation of its tablets. Each iPad is meticulously packaged to provide a premium unboxing experience for customers. The packaging is sleek, lightweight yet sturdy, and designed to showcase the elegance and sophistication of the device inside. | Transportation and Logistics Once the iPads are packaged, careful consideration is given to their transportation and delivery. The tablets are carefully loaded into secure containers, ensuring their safety during transit. Through strategic partnerships with reliable logistics providers, Apple ensures that the iPads reach their destinations promptly and intact. |

Distribution Channels Apple employs a multi-channel distribution strategy to reach a global market effectively. The iPads are distributed through various channels, including authorized resellers, online platforms, and Apple retail stores. This diverse distribution network enables a wide availability of the product to cater to different customer preferences and geographical locations. | Localization and Customization During the packaging and distribution process, Apple incorporates localization and customization efforts to cater to specific markets. This involves adapting product packaging, user manuals, and software to meet regional requirements and language preferences. By tailoring the iPads to each market, Apple ensures an enhanced user experience and seamless integration into different cultures. |

In conclusion, the packaging and distribution of Apple iPads undergo meticulous planning and execution. From visually stunning packaging to secure transportation, Apple aims to provide customers with a flawless unboxing experience. By utilizing a diverse distribution network and incorporating localization efforts, Apple ensures global availability and a tailored experience for users around the world.

[MOVIES] [/MOVIES] [/MOVIES_ENABLED]FAQ

What materials are used to make iPads?

iPads are made using various materials such as aluminum, glass, and plastic. The body of the iPad is typically made from a single piece of aluminum, while the screen is made of durable glass. The internal components are made up of silicon chips, circuit boards, and other electronic parts.

Where are iPads manufactured?

iPads are manufactured in several locations around the world, but a significant portion of them are manufactured in China. Apple has partnered with various factories and manufacturers in China to produce its devices. These factories are equipped with advanced machinery and skilled labor to ensure the production of high-quality iPads.

What is the production process of iPads?

The production process of iPads involves several stages. Firstly, the raw materials such as aluminum, glass, and electronic components are sourced from different suppliers. Then, the body of the iPad is manufactured through processes like CNC milling and precision machining. The screen is created by shaping and polishing the glass. After that, the electronic components are assembled on the circuit boards and integrated into the iPad's body. Finally, rigorous testing and quality control measures are implemented, and the iPads are packaged and prepared for shipping to retailers worldwide.